DRAWN CUP NEEDLE CLUTCH

|

Drawn

cup needle clutch HF series and HFZ series |

|

The

drawn cup needle clutch HF, HFZ series is composed of thin wall punched

outer ring and plastic retainer. There is a clamping slope which holds

the needles tightly on the inradius surface of the alloy steel punched

out ring . the abrasion resistance and load capacity is greatly increased

after special heat treatment. Metal springs are fitted on the plastic

retainer which keeps the correct movement of the needles while the

needles are used as clamping unit at the same time. Through

fitting RTL drawn cup needle roller bearing HK, SCE series of the

same diameter on the two sides of drawn cup needle clutch, better

supporting rigidity and rotation characteristics are achieved. |

drawn cup needle clutch HF/HFZ |

|

Drawn

cup needle clutch and bearing assembly HFL series and HFlZ series |

|

Drawn cup needle clutch and bearing

assembly HFL, HFLZ series has a two-in-one supporting bearing which

can be a special space-saving support. The supporting bearings fitted

be the two sides of the needle clutch bear the radical load . The

support bearings are needles and the plastic retainer. |

Drawn cup needle clutch and bearing assembly HFL/

HFlZ |

|

Torque

transmission capacity |

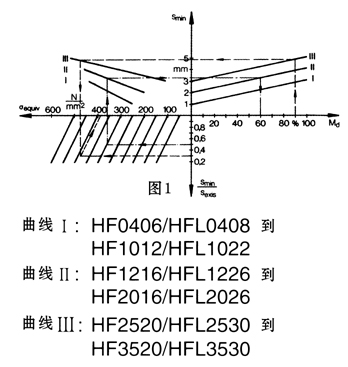

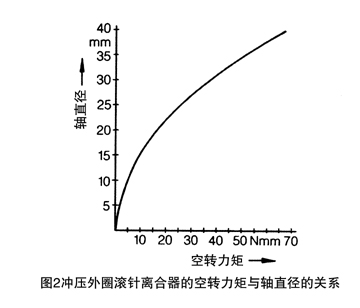

When the recommended assembling tolerances are adopted, the maximum transmitting torque is mainly decided by the

material, strength and wall thickness of the seat case and shaft. In a clutch, only enough wall thickness and appropriate material

strength can sustain the force resulted. Inertial force should be taken into account. For the equivalent caused by the torque and the

minimum wall thickness , please refer to Figure 1. The equivalent stress should be less than the stress permitted by the seat mat-

erial. For the relation between free torque and axle diameter , please refer toFigure 2.

|

Example: |

A known: drawn cup needle clutch HF3020

Load capacity: 90% of Md

Present wall thickness: Sexis=16mm

From Fig 1: minimum wall thickness Smin=4.8mm

Equivalent stress бequiv=380N/mm2

B; known: drawn cup needle clutch HF1416

Permissive stress of seat casing бperm=300N/mm2

Selective ratio of the seat casing wall thickness Smin/Sexis=0.5

From Fig 1: minimum wall thickness Smin=3.2mm

Permissive torque Md perm=60%Md

|

The switching frequency and

precision |

|

The

needle clutch has a very small torque due to its thin radical section.

Because each needle is supported by an independent spring, a constant

contacting is maintained among the slopes of shaft, needles and punched

outer ring, higher switching frequency and precision are allowed.

Beside the switching frequency, the switching precision is depended

on the selection of lubrication and combination. The elastic deformation

of the neighboring parts and driving force are transmitted through

the shaft or outer ring. The driving force is transmitted through

shaft when the frequency is high. |

|

|

Feature

inspection |

|

The tools used by the manufacturer in inspection

of drawn cup needle clutch are feeler gage and ring gage which are

in seat hole and shaft tolerance range N6/h5 upper limit and lower

limit. Meanwhile , the torque it sustains is approximately 0.15Md

perm. The feeler gage used is quenched steel ring with its aperture

precisely ground and the minimum wall thickness of 20mm. |

|

|

Operational

temperature and lubrication |

With good lubrication,RTL drawn cup needle clutch can be operated for a long time under the temperature between

-30℃-20℃. When the temperature is below -10℃or the speed is greater than 0.7 *nj, to ensure the normal functions of

the bearings, recommended lubricants should be selected. In most cases, there are enough lubricants. So the products

are filled in advance the quality lithium based grease in compliance with the national standards with the applicable

temperature from -10℃to 70 ℃. Oil lubrication is recommended when the temperature exceeds 70℃.

|

Mounting

tolerance |

|

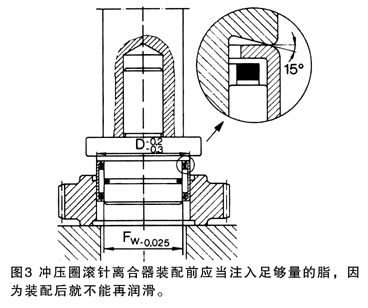

When

mounting , the shaft and the seat hole with a chamfered angle of 15

degrees will help to get the best fitting condition. The mounting

method is shown in Fig 3. The needles and the thin wall punched outer

ring of the clutch will get the concentric configuration only after

being fitted into the seat. No other axle positioning is necessary.

The mounting tolerance is the same as that of the drawn cup needle

bearing. See table 1. The seat hole surface roughnes is Ra0.8 . |

|

|

Bearing seat material (rigid

bearing seat) |

Bearing seat hole tolerance |

Shaft tolerance range Without inner ring |

Inner ring |

|

Steel and cast iron |

N6(N7) |

h5(h6) |

k5(j6) |

|

Light metal |

R6(R7) |

1) for non rigid bearing seats, fitting tests are needed to determine the required common tolerance limit so that the operational gap can be achieved.

2) The geometric precision of the cylinder shape of the bearing seat hole must fall into the half range of the value in IT5/2.

|

Special

reminding: |

1) Press the needle clutch into the seat hole with a fitting shaft . The clutch will be locked tightly when turning around in the arrow direction marked

on the side of clutch.. So, note the locking direction before fitting.

2) The close locking and overdrive clutching is possible only when the recommended tolerances are used.